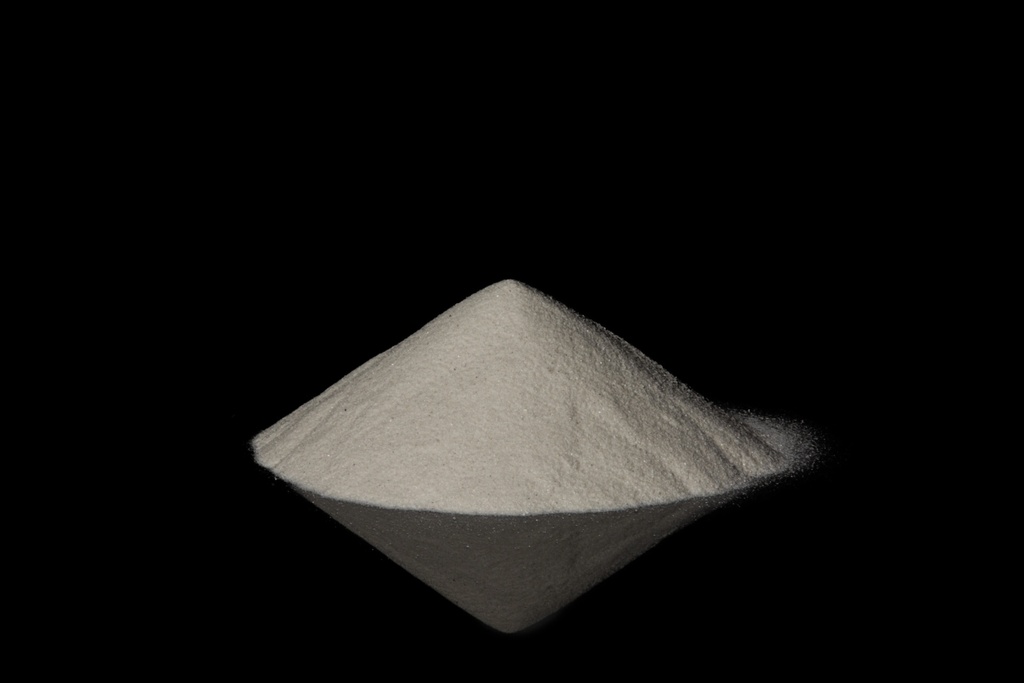

سیلیس (SiO2) دومین عنصر رایج ( % 25 فراوانی) در پوسته زمین است ، این ماده غیرفلزی و سخت است و بصورت بی رنگ و خاکستری در طبیعت میباشد و دارای مقاومت بسیار بالا میباشد .

موارد مصرف :

- صنایع کاشی و سرامیک و لعاب

- صنایع چینی

- صنایع ریخته گری

- صنایع تصفیه آب

- صنایع فروها

- شیمیایی

- صنایع الکترود

- صنایع کف پوش PVC

- صنایع باطری های سربی

- صنایع رنگ و بتونه

- ساینده

- لاستیک و پلاستیک

- سند بلاست

آنالیز شیمیایی:

| درصد S.K | درصد S.S | عناصر |

| 99.10 | 97.88 | SiO2 |

| 0.27 | 0.50 | Al2O3 |

| - | 0.05 | BaO |

| 0.44 | 0.15 | CaO |

| 0.02 | 0.35 | Fe2O3 |

| 0.008 | 0.05 | K2O |

| 0.05 | 0.11 | MgO |

| - | 0.05 | MnO |

| 0.01 | 0.05 | Na2O |

| - | 0.05 | P2O5 |

| - | 0.05 | SO3 |

| 0.14 | 0.41 | TiO2 |

| - | 0.59 | Loi |